We will solve customer`s problem in the best plan

Have advanced knowledge and the planning ability magnetic material professionals can support customers solve different problems

We will after hearing the problems, thoroughly reviewed the cost, production system, design specification, quality and delivery,and provide new solutions to customers

Please consult with our professional staff who have abundant experience and solved all kinds of problems

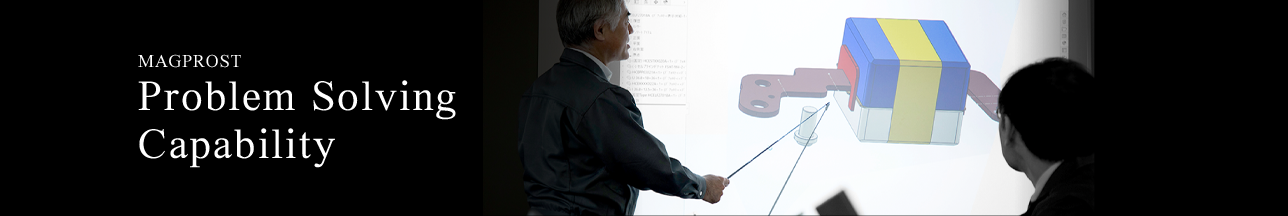

MAGPROST’s advantage

As a professional in magnetic manufacturing ,We satisfy our customers with higher precision and higher quality products,

Continuously improve“quality management ability ”“analysis ability ”“product ability”“development ability”“proposal ability”and strengthen the system,

Take the magnetic material as center,Continue to challenge and try to expand business possibilities.

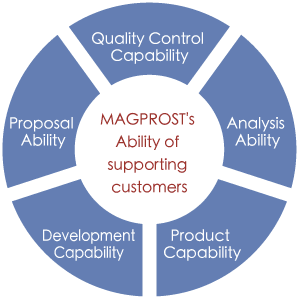

MAGPROST’s best Solution

After being commissioned, plan, file, sample, evaluate and analyze,and repeat confirmation of the project selection,after got the optimal evaluation results then enter the mass production

Moreover,The design adjustment and specification changes can also be quickly matched,Stable supply is achieved on the basis of the quality system within the company.

The implement of the best solution of magnetic material products

MAGPROST Problem solving case

The following case is that MAGPRST support all kinds of customers needs.

This one is the premise of “cost reduction”

While seeking to reduce costs, pursuit of solutions for customets’ problems continuously,We will continue to do our utmost to satisfy the demands of customers’ “want to” and “want”

「Space saving in EMC measures for EV and HEV」

Recently, EV and HEV units have been miniaturized every time the generation is renewed.

At the same time, EMC standards are also added and stricted.

In order to meet EMC standards in a limited space, it is necessary to select appropriate soft magnetic core materials and support production for installation cases with complex shapes.

However, we received consultation because there are no suppliers who can balance it and have a cost competitiveness.

We provided a CAD model of the unit that is expected to install emc countermeasure core, and immediately began selecting core materials and designing cases.

Since we handle everything from ferrite cores to nanocrystalline materials, we considered the selection of core materials without limiting them, and immediately selected the optimal core material.

After the core material selection, the case shape design is started. It was designed with the structure to obtain the maximum EMC countermeasure effect in limited space while considering vibration durability.

We delivered the initial sample with the core assembled to the case created with a 3D printer, and as a result of emc testing, we were able to meet EMC standards.

Because it was urgent, we were allowed to respond in a short delivery time of 30 days from the first consultation to the initial sample delivery.

It is an example that can cope with a wide range of core materials, and can cope with everything from the selection of core materials to the design of the case because we are able to handle it all at once.

「Measurement of inductance for direct current flow under high current conditions」

We tried to improve the specification based on the core specifications adopted, but we did not get the characteristics which were evaluated after the unit implementation.

It is evaluated under the current conditions of 200A, but it is said that 50A was the maximum for dc superimposed inductance actual evaluation for the core single item.

According to the measured value of 50A, the characteristics under 200Adc are calculated, and the specification improvement is studied.

The failure to get the expected characteristics is due to the deviation between the calculated characteristics and the measured characteristics. It is necessary to investigate the measured characteristics in this case.

As a response to our company, we measured the candidate core specification obtained by computer calculation under the current conditions of 200Adc, and established the specification.

We were able to take measures with a core specification that was cheaper than the core specification that was originally considered, and we were able to realize a significant cost reduction.

It is an example that can be dealt with because we have a direct-view flow superimposed inductance measurement system that can measure up to 400A.

【Strategy about《Whether the material used is suitable or not》for cost reduction】

When we confirmed the magnet specification,focus on the shape of the difficulty of magnetization,it’s impossible to achieve the magnetic property

Analyze the results of using magnets,make some adjustments in the direction of magnetization in the same shape,can lower the grade of the material.

So we proposed a reduction of two levels 5 meterial.The torque characteristic of the motor was reduced by about 3%,but it’s within the tolerance range of the properties,The judgment is completely usable.

Other types of machines also unfold horizontally,reduced the cost of tens of millions yen successfully.

This is because we are familiar with the forming of magnets in magnetic fields,so this can be proposed

【Build on basic data,Proposal of cutting engineering 】

In order to avoid detection errors during the shock from the door switch,take the tiny adjustment of magnets during assembly

For a long time,How to reduce the adjustment of magnet became a project,but there is still no satisfactory solution.

Understand the movable area of the door and the detection area of the switch sensor,then verified the compatibility of the magnetic force line.Found that the Angle management of magnetic force line is the reason.

Our proposal was adding geometry specification requirements on the magnets.And asked customers to evaluate the improved products,turned out that we don’t need to adjust the position of the magnets

In addition,We already collected magnetic field data of the entire magnet under 30 conditions,and established basic database . As a result, even changed the specifications of the door,

can also set the installation conditions of sensors and magnets according to basic data.Cut the numbers of projescts successfully and stability.

Because we can make evaluation of the magnetic power line visualization of the magnet,so this can be proposed

【Through the variation of magnet types and magnetic waveform ,Improve reliability and small, lightweight】

The temperature must be high,The thermoplastic countermeasures of injection molding magnets have become the main project

PPS medium is qualified for the performance ,but the price is high and the cost don’t match. There is an advantage in the cost of nylon,but thermoplastic is not required.

After receivied the consultation, first was to solve the problem of the physical reliability ,so took the isotropic sintered ferrite that is no problems on the thermoplastic side as a backup.

Customers also had some knowledge of such magnets,analysised of software by magnetic field ,it’s magnetism couldn’t reach the reaction requirement.

Take advantage of our professional knowledge of magnetic fixture,solved this problem by adjusting the magnetic waveform

It is also made isotropic sintered ferrite obtained the magnetic force.

The outer diameter of the injected plastic forming magnet was discussed for φ20,after used the isotropic sintered ferrite, the size of the outside diameter was improved to φ15,

Successfully made the whole device light weight miniaturized

Due to rich experience in magnetizing,learned professional skills at the same time,so this can be proposed

The industrial territories of MAGPROST

-

Automotive industry●A proposal for Small, lightweight ●A proposal for considering production engineering capacity

●A proposal for consider quality assurance, stable supply, cost performance -

Household appliance industry●A proposal for the specification of cost performance ●A proposal for a flexible supply system that can rapidly adjust production conditions for emergencies ●A flexible supply system for short-term development

-

Safety industry●A proposal for improving the efficiency of the specification ●A proposal for the most appropriate material for the environment ●A proposal for suppressing the sensors misstart happen

-

Medical industry●A proposal for suppressing the influence of the surrounding environment magnetic field’s specifications ●A proposal for a flexible supply system for small quantities of orders ●A proposal for considering USES & the most appropriate materials for the environment

-

Robot industry●A poposal for saving power, the most suitable specification for high torque ●A proposal for Small, lightweight ●A proposal for a flexible supply system for small quantities of orders

-

Power industry●A proposal for efficient specifications ●A proposal for Small, lightweight ●A proposal for a flexible supply system from a small amount to a large number of orders for both side

-

Equipment industry●A proposal for the most appropriate specification of frequency of using ●A proposal for efficient specifications ●A proposal from material to assembly are subject to requirements